1. Introduction

3D printing isn’t just about pressing “print”—it involves navigating different file formats, each serving a crucial role in the workflow. This is why you need to understand 3D printing file formats. Whether you’re downloading a model from an online repository or designing your own creation, understanding how these file types interact can save you time and frustration.

Different 3D printing file formats store models in various ways. Some retain editable design data for modifications, while others strip the model down to just its surface geometry. And before a printer can bring your design to life, it needs a specialized format—one tailored to its specific hardware.

This guide walks through everything from design files to printer-ready instructions, helping you avoid common pitfalls and optimize your workflow.

Next up: Design File Formats—where 3D models start their journey. Ready to dive in?

2. Design File Formats (For 3D Modeling)

Before you slice a model for 3D printing, you need a design file that captures your creation. These 3D printing file formats store 3D geometry in a way that allows for edits, modifications, and precise adjustments before finalizing the print.

Common Design File Formats

- STP / STEP (.stp, .step)

- Standard in engineering and mechanical design.

- Supports precise geometric definitions.

- Ideal for complex parts and professional CAD workflows.

- IGES (.igs, .iges)

- Another CAD format used in industries requiring high-accuracy models.

- Stores curve-based designs instead of mesh-based models.

- Less commonly used for 3D printing but valuable for transferring CAD data.

- 3MF (.3mf)

- A modern alternative to STL with added metadata and material properties.

- Supports textures, colors, and advanced settings.

- Increasingly used for full-featured slicing and multi-material printing.

- BLEND (.blend)

- Blender’s native file format.

- Stores 3D models with all their textures, animation data, and modifiers.

- Excellent for artistic and sculptural work but requires conversion for printing.

- SKP (.skp)

- Used in SketchUp, favored by architects and hobbyists.

- Stores models with layers and annotations.

- Requires conversion for 3D printing compatibility.

When Do You Use These Formats?

- If you’re designing from scratch, 3D printing software like Fusion 360, SolidWorks, or Blender will save files in these formats.

- These are editable files, meaning you can modify parameters like shape, dimensions, and internal structure.

- They do not go directly into a slicer—you must export the design as a mesh format like STL or OBJ before slicing.

Next up: Mesh File Formats—the bridge between design and slicing! Ready?

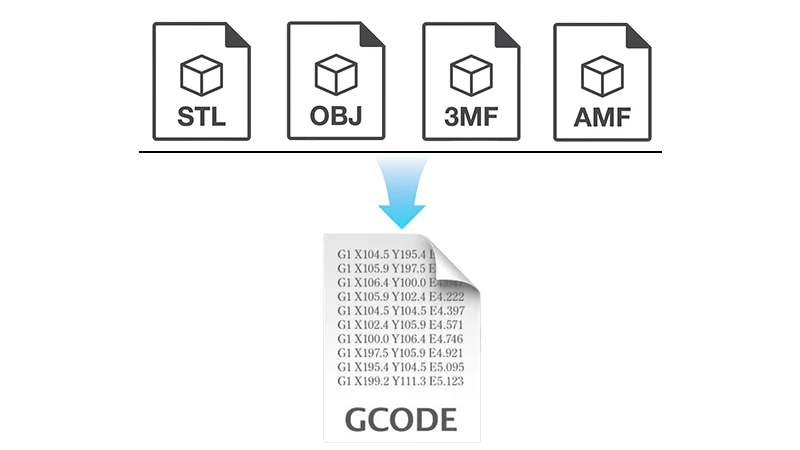

3. Mesh File Formats (For 3D Printing)

Once a design file is finalized, it needs to be converted into a mesh format before slicing. These formats describe the 3D object’s surface geometry using triangles, but they don’t retain editable parameters like sketches or dimensions.

Common Mesh File Formats

- STL (.stl)

- The most widely used format in 3D printing.

- Stores geometry as a triangular mesh (without color or material data).

- Compatible with almost all slicers.

- OBJ (.obj)

- Similar to STL but supports textures and colors.

- Ideal for full-color or multi-material 3D printing.

- Often used in 3D rendering and animation as well.

- PLY (.ply)

- Originally developed for 3D scanning.

- Can store detailed surface and color information.

- Used in advanced applications requiring rich model data.

How Do These Formats Work in a Workflow?

- If you download an STL file, you’re working with surface geometry only.

- If you need textures or colors, an OBJ file might be the better choice.

- These can be imported directly into slicer software (e.g., Cura, PrusaSlicer, Bambu Studio).

The next step? Slicing these models into printer-ready instructions! Let’s move on to Slicer File Formats.

4. Slicer File Formats (For Printing Instructions)

Once you’ve loaded an STL or OBJ file into a 3D model slicer, the next step is translating it into machine-readable instructions. These instructions tell the printer exactly how to move, what temperatures to maintain, and how fast to extrude filament.

Common Slicer File Formats

- G-code (.gcode)

- The universal format for 3D printing instructions.

- Contains precise layer-by-layer commands for the printer.

- Important: G-code is printer-specific—settings like speeds, temperatures, and movement vary by brand and model!

- Generated by slicer software like Cura, PrusaSlicer, Bambu Studio, and OrcaSlicer.

- X3G (.x3g)

- Used by older MakerBot printers.

- Converts G-code into a format compatible with specific firmware.

- Less common today, but occasionally needed for legacy hardware.

- AMF (.amf)

- Advanced format capable of storing material properties and color details.

- Supports multi-material and lattice structures.

- Not widely adopted but offers potential for future developments.

From Slicer to Printer

- Your slicer processes a mesh file and generates G-code tailored to your printer’s firmware.

- The G-code file is not interchangeable between different printers unless settings match exactly.

- You transfer this file via USB, SD card, or direct network connection for printing.

Next up: Choosing the Right 3D printing file formats based on specific needs. Let’s wrap this up efficiently!

5. Choosing the 3D printing File Formats

Now that we’ve covered the different types of 3D printing file formats, how do you decide which one to use? Your choice depends on where you are in the workflow—designing, downloading, slicing, or printing.

Best Format for Designing & Editing

- STEP / STP: Ideal for precise engineering models.

- BLEND: Best for artistic creations using Blender.

- SKP: Good for architectural designs.

- If you’re working in CAD software, you’ll want a format that retains design history and parameters.

Best Format for Sharing & Downloading Models

- STL: The most widely accepted format for sharing printable models.

- OBJ: Useful when color and texture matter.

- 3MF: Great for retaining additional data beyond geometry.

Best Format for Slicing & Printing

- G-code: The final instructions sent to the printer.

- X3G: Needed for older MakerBot printers.

- AMF: Advanced but less commonly supported.

- Remember: G-code files are printer-specific, meaning settings must match the target printer exactly!

6. Conclusion

Understanding file formats is essential for avoiding printing errors, choosing the right software, and optimizing workflow. Whether you’re designing from scratch, downloading a ready-made model, or preparing for a print, the right format ensures everything runs smoothly.

As 3D printing technology evolves, new formats like 3MF and AMF are improving the way we handle textures, materials, and complex models. Staying informed helps you maximize efficiency and get the best results from your prints.