Introduction

Welcome to the world of 3D printing and 3D printers, where creativity meets technology to turn your ideas into reality. Whether you’re a curious beginner, an enthusiastic hobbyist, or a seasoned professional, finding the right 3D printer can make all the difference in your projects. This guide is designed to help you navigate the vast landscape of 3D printers, tailored to your unique needs and goals.

From understanding the different types of printers and technologies to exploring their applications across various industries, this resource dives deep into everything 3D printing. You’ll find in-depth reviews, comparisons, and tips to guide your purchase, along with inspiring case studies and fun project ideas. Along the way, I’ll share personal anecdotes to keep things relatable and practical, plus expert insights from the 3D printing community to ensure you’re making informed decisions.

Let’s embark on this journey together and uncover the best affordable 3D printers for kids, high-precision 3D printers for engineers, and top 3D printers for small businesses. Whether you’re building a prototype, teaching a classroom, or simply experimenting for fun—dive in and let your imagination take shape!

Table of Contents:

- Section 1 – Printers by User Type (Target Audience)

- Section 2 – Printers by Technology

- Section 3 – Printers by Industry

- Section 4 – Printer Comparisons

- Section 5 – Maintenance and Troubleshooting

- Summary

Section 1: Printers by User Type (Target Audience)

Choosing the right 3D printer largely depends on who will be using it. The needs of a curious child experimenting with their first design are vastly different from those of an experienced engineer designing intricate prototypes. In this section, we’ll explore various user categories—children, hobbyists, professionals, and engineers/designers—each with tailored recommendations, projects, and applications. Whether you’re aiming for simplicity, affordability, or cutting-edge technology, we’ve got you covered.

Table 1: Features and User Compatibility

| User Type | Safety Features | Ease of Use | Budget-Friendly | High Precision | Advanced Functionality |

|---|---|---|---|---|---|

| Children/Educational | ✔️ Enclosed designs, non-toxic materials | ✔️ Beginner-friendly interfaces | ✔️ Affordable options | ❌ Limited precision | ❌ Basic functionality |

| Hobbyists | ❌ Depends on model | ✔️ Moderate ease, DIY kits | ✔️ Wide range of prices | ❌ Moderate precision | ✔️ Multi-material printing |

| Professionals | ❌ May lack focus on safety features | ✔️ User-oriented tools | ❌ Higher price range | ✔️ Exceptional precision | ✔️ Advanced capabilities |

| Engineers/Designers | ❌ Safety secondary to precision | ❌ Requires technical expertise | ❌ Premium cost models | ✔️ Industry-grade precision | ✔️ CAD integration, exotic materials |

Table 2: Key Features by Printer Type

| Printer Type | Ideal for Beginners | Suitable for Complex Designs | Fast Print Speeds | Supports Exotic Materials | Low Maintenance |

|---|---|---|---|---|---|

| FDM Printers | ✔️ Simple and user-friendly | ❌ Moderate complexity | ✔️ Good speeds | ❌ Limited material options | ✔️ Easy to maintain |

| SLA Printers | ❌ Steeper learning curve | ✔️ High detail and complexity | ❌ Slower speeds | ❌ Limited to resins | ❌ Resin handling required |

| SLS Printers | ❌ Advanced expertise required | ✔️ Excellent for intricate designs | ✔️ Good speeds | ✔️ Supports advanced materials | ❌ Higher maintenance costs |

| Multi-Material | ❌ Not beginner-friendly | ✔️ Versatile for complex objects | ❌ Varies by model | ✔️ Exceptional flexibility | ❌ Complexity adds to upkeep |

Children/Educational

3D printers designed for children prioritize safety, ease of use, and fun. Features like enclosed printing areas and non-toxic materials make them ideal for young learners. For example, printers like the XYZprinting da Vinci Mini have gained popularity for their affordability and user-friendly design.

Fun starter projects for children could include printing miniature figurines, keychains, or basic geometric shapes that encourage creativity without overwhelming them with complexity. Affordable and safe options like the Flashforge Finder have proved to be excellent introductory printers.

Anecdote: I once saw a classroom transform with 3D printing—students created unique board game pieces for their project on game theory. Seeing their excitement as their designs came to life was remarkable!

External Resource: Find more educational 3D printing ideas at www.3dprintingeducation.org.

Hobbyists

For hobbyists, 3D printing is all about creativity, exploration, and experimentation. Affordable printers such as the Creality Ender 3 are great starting points, offering quality prints without breaking the bank. DIY kits like the Prusa i3 MK3 provide an added dimension of fun, allowing enthusiasts to assemble their own machine.

Popular fun hobby projects include printing personalized phone cases, cosplay accessories, or home decor items. Hobbyists also appreciate multi-material options for more complex designs.

Anecdote: A friend of mine built a fully functional remote-controlled car using a DIY 3D printer kit—it took weeks of trial and error, but the result was nothing short of spectacular.

External Resource: Learn more about hobbyist projects at www.hobby3dprinting.com.

Professionals

Professionals require reliable, high-performance machines that can handle demanding tasks. High-end models like the Ultimaker S5 or Formlabs Form 3 are favored for their advanced features and exceptional precision. For small businesses and makerspaces, printers such as the Raise3D Pro2 strike a perfect balance between cost and capability.

Case studies often highlight how professionals use 3D printing for prototyping, product development, and custom manufacturing. For example, dental clinics have integrated 3D printing to create molds for prosthetics and aligners.

Anecdote: I once collaborated with a small business owner who used their 3D printer to design unique lampshades—it became a signature product that boosted their brand visibility.

Engineers and Designers using 3D Printers

For engineers and designers, precision and compatibility with CAD software are paramount. Industrial-grade printers like the Markforged X7 or Stratasys F370 are ideal for producing prototypes with tight tolerances. Printers specifically designed for industry-specific applications can be found in fields like aerospace and automotive, where 3D printing is revolutionizing manufacturing processes.

CAD integration enables designers to streamline workflows by directly importing and modifying files. Using materials such as carbon fiber or metal-infused filaments allows for durability and versatility in creating parts for functional testing.

Anecdote: An aerospace engineer once shared how their team created a custom jet engine component using a 3D printer—it saved months of development time and showcased the immense potential of additive manufacturing.

Return to TopSection 2: Printers by Technology

The foundation of any 3D printer lies in its technology, which determines its capabilities, material compatibility, and output quality. Whether you’re a beginner searching for the best FDM printers for educational purposes, a jewelry designer in need of the best SLA printers for intricate designs, or an engineer seeking high-precision SLS printers for industrial use, understanding these technologies is key to making the right choice.

In this section, we’ll dive into the most common 3D printing technologies—FDM, SLA, and SLS—along with emerging advancements like multi-material and hybrid 3D printers. You’ll also find practical examples of their applications, pros and cons, and recommendations for top models.

Fused Deposition Modeling (FDM) are 3D Printers

FDM is the most accessible 3D printing technology, favored by beginners and hobbyists for its simplicity and affordability. It involves melting filament and depositing it layer by layer to create an object.

- Pros and Cons: FDM printers are affordable and easy to use, making them top-rated FDM printers for hobbyists. However, they have limitations in detail resolution and may encounter issues like warping or stringing.

- Best FDM Printers: The Creality Ender 3 and Prusa i3 MK3 are widely considered top FDM printers for hobbyists in 2025 due to their reliability and cost-effectiveness.

Anecdote: A friend used their FDM printer to create a fully functional camera slider for their photography setup. Despite being a beginner, the project turned out great after a few practice runs!

Stereolithography (SLA)

SLA printing uses a UV laser to cure liquid resin, producing highly detailed and smooth outputs. It is especially suited for professionals in design, dental, and jewelry industries.

- Intro to Resin Printing: SLA printers require handling liquid resin, which offers unmatched precision. They are the best SLA printers for dental applications and jewelry design.

- Best SLA Printers: Affordable options like the Elegoo Mars allow entry-level users to explore resin printing, while the Formlabs Form 3 remains a leading choice for professionals.

Anecdote: A jewelry designer I spoke to shared how switching to SLA printing cut her prototyping time in half, allowing her to bring designs to market faster than ever.

Selective Laser Sintering (SLS)

SLS technology utilizes a laser to fuse powdered material, creating durable and complex parts. It’s a go-to solution for SLS printers for aerospace engineering and industrial manufacturing.

- Overview: SLS printers can handle a wide range of materials, including nylon, composites, and even some metals, without needing support structures.

- Best SLS Printers: Models like the Fuse 1 from Formlabs are highly regarded as best SLS printers for functional prototypes and industrial-grade projects.

Anecdote: An automotive engineer used an SLS printer to create custom components for a race car, reducing production time and ensuring the part met rigorous performance standards.

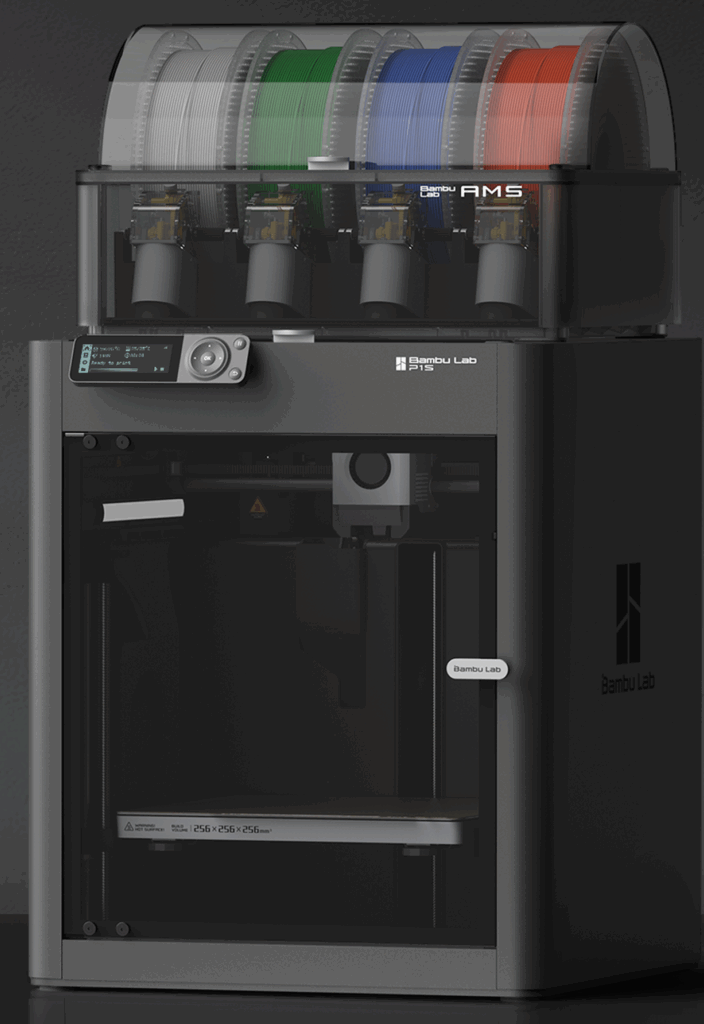

Other Technologies: Multi-Material and Hybrid 3D Printing

Emerging technologies like multi-material and hybrid 3D printers are paving the way for innovative applications.

- Multi-Material Printers: These printers support advanced designs by combining different materials in a single print, making them ideal for experimental designs.

- Hybrid Printers: Combining 3D printing with CNC machining or laser cutting, hybrid printers are a game-changer for advanced manufacturing.

Table 1: Technology Overview and Features

| Technology | Ease of Use | Detail/Precision | Material Options | Ideal Applications |

|---|---|---|---|---|

| FDM | ✔️ Beginner-friendly | ❌ Moderate | ✔️ Wide (PLA, ABS, PETG) | Prototyping, hobby projects, education |

| SLA | ❌ Steeper learning curve | ✔️ High | ❌ Limited (Resins) | Jewelry, dental models, small parts |

| SLS | ❌ Advanced expertise required | ✔️ Excellent | ✔️ Advanced (Nylon, composites) | Industrial parts, functional prototypes |

| Multi-Material | ❌ Not for beginners | ✔️ Varies by model | ✔️ Exceptional flexibility | Experimental and complex designs |

| Hybrid | ❌ High complexity | ✔️ Precision plus versatility | ✔️ Multiple (3D + CNC/laser) | Advanced manufacturing, intricate objects |

Table 2: Pros and Cons of Technologies

| Technology | Pros | Cons |

|---|---|---|

| FDM | Affordable, easy to maintain, accessible materials | Limited detail, warping issues, lower strength |

| SLA | High accuracy, smooth finishes | Expensive resins, slower speeds, requires post-processing |

| SLS | No support structures needed, durable parts, wide material options | Costly equipment, higher maintenance requirements |

| Multi-Material | Combines materials, ideal for advanced experimentation | Expensive, steep learning curve |

| Hybrid | Combines multiple functions (e.g., printing + cutting), versatile | High initial cost, complexity of operation |

Section 3: Printers by Industry

Introduction

Industries around the globe are embracing 3D printing to revolutionize how products are designed, developed, and manufactured. From creating life-saving prosthetics in healthcare to prototyping innovative car components in automotive engineering, 3D printing has countless applications across sectors. In this section, we’ll explore how specific industries leverage 3D printing technology, focusing on key applications, ideal printer features, and real-world success stories.

Whether you’re an educator looking for the best printers for schools, an architect aiming to create high-resolution models, or a healthcare professional seeking biocompatible 3D printers for medical devices, this guide will help you understand the role of 3D printing in your field.

Healthcare

3D printing in healthcare has unlocked groundbreaking possibilities, from producing prosthetics and implants to creating patient-specific anatomical models. Biocompatible materials and high precision are essential in this field.

- Applications: The best biocompatible 3D printers for medical devices can be used to create custom prosthetics, dental aligners, and surgical guides.

- Key Features: High accuracy, biocompatible materials, and the ability to produce complex geometries.

- Case Study: A hospital used a resin SLA printer to create a surgical guide for a rare operation, allowing the surgical team to plan with precision and reduce operation time.

Anecdote: I once read about a healthcare provider that utilized 3D-printed anatomical models to communicate with patients about upcoming surgeries—it made a huge difference in patient understanding and trust.

Automotive

The automotive industry relies on 3D printing for rapid prototyping, tooling, and even producing end-use parts. Large-format printers and materials like carbon fiber-reinforced polymers are highly valued.

- Applications: Large-format 3D printers for automotive prototyping are ideal for creating lightweight components, aerodynamic parts, and custom interior details.

- Key Features: Durability, speed, and the ability to print at a large scale.

- Case Study: A race car team used a 3D printer to prototype and test custom airflow components, significantly improving their vehicle’s performance during competition.

Anecdote: I once visited a car show where a custom concept car had its dashboard entirely designed and 3D printed—it was a perfect blend of artistry and engineering.

Architecture

In architecture, 3D printing enables the production of highly detailed scale models, reducing the time and cost associated with traditional techniques.

- Applications: High-resolution 3D printers for architectural models can bring complex designs to life with striking precision.

- Key Features: High resolution, multi-material compatibility, and large build volumes for bigger models.

- Case Study: An architecture firm used a resin printer to create a scaled model of a city block for a client presentation. The realistic details helped secure project approval.

Anecdote: I once saw an architect combine 3D-printed models with augmented reality to present their vision. It was fascinating how the physical and virtual worlds merged seamlessly.

Education

Education is one of the fastest-growing sectors for 3D printing adoption. Schools and universities use it to promote STEM learning and foster creativity in students.

- Applications: The best printers for schools offer durable and easy-to-use designs that can handle frequent use in classrooms.

- Key Features: Safety features, affordability, and compatibility with educational tools or software.

- Case Study: A high school implemented 3D printers to create engineering prototypes, leading to student participation in a national design competition.

Anecdote: A teacher shared how students used a 3D printer to create historical artifacts for a project, making history lessons far more engaging and hands-on.

Table 1: Industry Applications and Key Features

| Industry | Applications | Key Features | Example Printers |

|---|---|---|---|

| Healthcare | Prosthetics, surgical guides, dental models | High precision, biocompatible materials | Formlabs Form 3, EnvisionTEC Perfactory |

| Automotive | Prototypes, custom parts, tooling | Large build volume, carbon-fiber compatibility | Raise3D Pro2, BigRep One |

| Architecture | Scale models, presentations | High resolution, multi-material options | Ultimaker S5, Anycubic Photon |

| Education | STEM learning, classroom projects | Safety features, ease of use, affordability | Flashforge Finder, XYZprinting da Vinci |

Table 2: Common Challenges by Industry and Solutions

| Industry | Common Challenges | Solutions |

|---|---|---|

| Healthcare | Limited biocompatible materials | Use resin-based SLA printers designed for medical use |

| Automotive | Long production time for large parts | Leverage large-format printers with faster speeds |

| Architecture | Difficulty in achieving detailed models | Invest in high-resolution printers with resin technology |

| Education | Budget constraints for schools | Apply for grants and funding options for educational tools |

Section 4: Printer Comparisons

Choosing the right 3D printer often comes down to comparisons—whether it’s the budget, features, or brand preferences. In this section, we’ll delve into detailed comparisons to help you make an informed decision. From finding top 5 printers under $500 to deciding between Prusa vs Creality for your specific use case, this guide will provide the clarity you need to make the perfect choice.

Each comparison is tailored to different needs, ensuring you can find a printer that aligns with your goals and priorities, whether you’re on a budget, seeking advanced functionality, or simply looking for the best value for money.

Budget Comparisons

For budget-conscious users, price matters—but so does performance. Finding a printer that balances affordability with quality can be tricky, but here are some great options.

- Top 5 Printers Under $500: Models like the Anycubic i3 Mega and Creality Ender 3 remain popular for their excellent build quality and reliability without breaking the bank.

- Value vs Performance: Affordable SLA printers for small businesses often offer better detail resolution for professional tasks, while lower-cost FDM printers excel in everyday use cases.

Anecdote: A hobbyist friend wanted a budget-friendly option for cosplay props and ended up choosing the Creality Ender 3. Despite its low price, the printer churned out impressive results after a bit of tweaking!

Feature Comparisons

Features often define the capabilities of a 3D printer. Whether you need large build volumes or support for exotic materials like carbon fiber, understanding the key features is essential.

- Printers with Large Build Volumes: Large-format 3D printers for automotive prototyping, like the BigRep One, are excellent for creating sizable objects.

- Printers Supporting Exotic Filaments: Models such as the Raise3D Pro2 excel in handling challenging materials like carbon fiber or metal-infused filaments.

Anecdote: A small business owner shared how their printer’s ability to work with carbon fiber filaments opened doors to create premium-looking products that helped boost sales.

Brand Comparisons

The choice between major brands often boils down to specific needs and preferences. This section highlights popular comparisons to help you decide.

- Prusa vs Creality: For hobbyists, Prusa vs Creality often comes down to ease of use vs cost-effectiveness. While Prusa printers are known for their reliability and smooth operation, Creality offers incredible value for the price.

- Popular Brands Breakdown: Brands like Anycubic, Formlabs, and Raise3D each have their strengths—whether it’s affordability, precision, or advanced functionality.

Anecdote: A colleague opted for a Creality printer to save on costs but later upgraded to a Prusa for its smoother operation and fewer troubleshooting requirements.

Table 1: Budget-Friendly Options and Features

| Price Range | Top Models | Pros | Cons |

|---|---|---|---|

| Under $500 | Creality Ender 3, Anycubic i3 Mega | Affordable, beginner-friendly | Limited precision, fewer advanced features |

| $500 – $1,000 | Prusa i3 MK3, Flashforge Creator Pro | Great build quality, reliable | Higher upfront cost |

| $1,000+ | Raise3D Pro2, Formlabs Form 3 | Premium features, precision | Expensive, requires expertise |

Table 2: Feature Comparisons Across Printers

| Feature | Example Printers | Applications | Challenges |

|---|---|---|---|

| Large Build Volume | BigRep One | Automotive, large prototyping | High cost, space requirements |

| Exotic Filaments | Raise3D Pro2 | Carbon fiber, metal-infused projects | Requires premium printers, expertise |

| Ease of Use | Prusa i3 MK3, Flashforge Finder | Hobbyists, classrooms | Fewer advanced customization options |

Section 5: Maintenance and Troubleshooting

Owning a 3D printer comes with the exciting possibility of creating incredible designs—but maintaining your printer is just as important. Proper care ensures your printer performs at its best and lasts longer, while troubleshooting common issues like warping and under-extrusion helps you avoid unnecessary frustration. This guide will cover essential maintenance checklists for 3D printers, tips for how to clean a 3D printer nozzle effectively, and much more.

For both beginners and experienced users, understanding how to extend the lifespan of your 3D printer and upgrading it for better performance is key to getting the most out of your investment.

Printer Maintenance

Keeping your 3D printer in peak condition requires regular cleaning, lubrication, and calibration. Following a routine maintenance schedule can prevent most common issues.

- Cleaning and Lubrication Tips: How to clean a 3D printer nozzle effectively is one of the most frequently asked questions in 3D printing. Regularly clean nozzles with a wire brush and use isopropyl alcohol to wipe down the print bed. Lubricate the bearings and rods monthly to avoid friction-related wear.

- Extending Printer Lifespan: Proper storage is essential—keep your printer in a cool, dry place and use a dust cover. Avoid low-quality filaments that can clog nozzles and strain your printer.

Anecdote: A friend once used cheap filament that caused constant clogging and eventually damaged their printer’s hotend. After switching to higher-quality materials, their printing experience improved drastically!

Troubleshooting Common Issues

Even with regular maintenance, problems can arise. Knowing how to fix printing errors like warping and stringing can save your prints and your time.

- Warping Issues: Warping occurs when the edges of a print lift off the bed. Troubleshooting warping issues in FDM printers starts with ensuring a level bed, using adhesives like glue sticks, or enabling a heated bed.

- Stringing Problems: Stringing happens when excess filament strands connect different parts of your print. Adjusting retraction settings and print temperature helps resolve this. How to fix stringing problems in 3D printing is a must-know skill.

- Under-Extrusion: This issue occurs when the printer fails to extrude enough filament, leading to weak or incomplete prints. The solution often involves checking the nozzle for clogs or ensuring proper filament feeding.

Anecdote: A professional once shared how they fixed persistent stringing issues by lowering the print temperature slightly and fine-tuning retraction settings, transforming their print quality overnight.

External Resource: Discover more troubleshooting tips at [www.3dprintertroubleshooting.com].

Upgrades and Modifications

Upgrades can significantly improve your printer’s performance and capabilities, and DIY modifications for 3D printers allow for customization to meet specific needs.

- Essential Upgrades: Adding a glass print bed ensures better adhesion and a smoother surface for your prints. Installing an all-metal hotend allows for compatibility with high-temperature materials like nylon and polycarbonate.

- DIY Modifications: Building enclosures to regulate temperature and reduce noise is a popular upgrade. DIY enclosures for 3D printers not only improve print quality but also make your setup more professional.

Anecdote: I once saw a user turn their printer enclosure into a visually striking workstation with LED lighting and automated ventilation—it was both practical and aesthetically amazing.

Table 1: Maintenance Checklist

| Task | Frequency | Tools Needed |

|---|---|---|

| Clean Print Bed | After every print | Isopropyl alcohol, scraper |

| Lubricate Bearings | Monthly | Lubricant, lint-free cloth |

| Check Belt Tension | Bi-weekly | Allen key, tension gauge |

| Replace Nozzle | As needed | Wrench, compatible nozzle |

Table 2: Troubleshooting Quick Guide

| Issue | Possible Cause | Solution |

|---|---|---|

| Warping | Poor bed adhesion, uneven heating | Use adhesive, ensure heated bed is calibrated |

| Stringing | Incorrect retraction settings, high temperature | Adjust retraction and lower temperature |

| Under-Extrusion | Clogged nozzle, filament feed issues | Clean nozzle, check filament path |

| Layer Shifting | Loose belts, unstable frame | Tighten belts, ensure printer is on a stable surface |

Summary: Your 3D Printing Journey Starts Here

3D printing is a transformative technology that empowers creativity, innovation, and problem-solving across various fields. Whether you’re a beginner looking for the best FDM printers for educational purposes, a professional seeking high-precision SLS printers for industrial use, or a hobbyist exploring DIY modifications for 3D printers, there’s a perfect solution waiting for you. By understanding the user types, technologies, industry applications, comparisons, and maintenance, you’re equipped to make informed decisions and unleash the full potential of 3D printing.

The world of 3D printing evolves rapidly, offering limitless possibilities for education, healthcare, engineering, and beyond. With the insights and tips provided in this guide, you’re ready to dive in and bring your ideas to life, one layer at a time.

Call to Action: Take the Next Step

Ready to get started? Explore our detailed pages to find the best printer for your needs, learn how to maintain and troubleshoot your machine, or discover exciting new projects to try. Whether you’re looking to invest in your first printer or upgrade to a cutting-edge model, we’re here to guide you every step of the way.

- 3D Printer Users

- 3D Printing Technologies

- 3D Printing Industry

- 3D Printer Comparisons

- 3D Printer Maintenance

Start building your future today—dive deeper into 3D printing and make something incredible. After all, the only limit is your imagination!