Basic 3D Printer Bed Leveling Explained for Beginners

1. Introduction to Bed Leveling

Why Bed Leveling Matters for Print Success

A short tutorial on 3D Printer Bed Leveling Explained. Bed leveling is one of the most critical factors in achieving high-quality prints. A properly leveled bed ensures that the first layer adheres evenly to the surface, preventing issues like warping, poor adhesion, or uneven prints. For 3D printing beginners, understanding bed leveling helps eliminate frustration and improves print consistency.

Common Issues Caused by an Unlevel Bed

When the bed isn’t correctly leveled, you may encounter problems such as:

- Poor first-layer adhesion: The print doesn’t stick well to the bed, leading to failed prints.

- Uneven extrusion: Some areas of the print are too squished, while others appear too loose.

- Nozzle scraping or hovering: The nozzle may be too close or too far from the bed, causing inconsistent layers or even clogging.

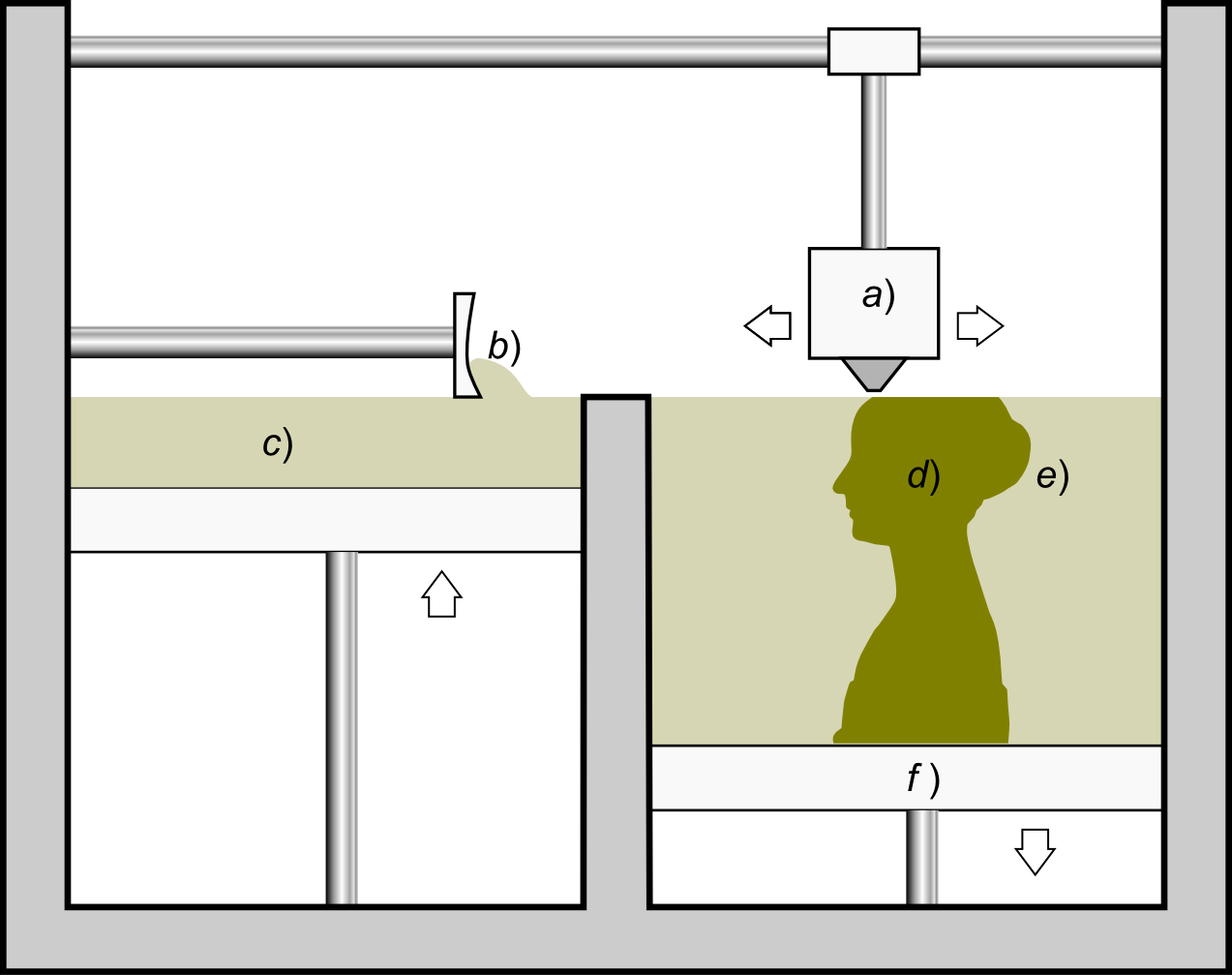

Overview of Different Bed Leveling Methods

There are two main approaches to bed leveling:

- Manual Leveling: Uses adjustment screws under the bed to fine-tune its position, often with a paper test.

- Automatic Bed Leveling: Utilizes sensors (like BLTouch or inductive probes) to measure and compensate for surface irregularities.

Getting the bed properly leveled is a foundational skill for 3D printing. When you go to buy your 3D printer, this is a feature you need to investigate. In the next section, we’ll dive into manual and automatic leveling methods to see which one works best for beginners.

2. Manual vs. Automatic Bed Leveling

Manual Bed Leveling: How It Works

Manual bed leveling requires adjusting the height of the print bed using small screws located underneath. Typically, this process involves:

- The Paper Test: Sliding a piece of paper between the nozzle and bed to gauge the correct distance.

- Tuning the Screws: Gradually tightening or loosening the bed leveling knobs to achieve uniform spacing across the surface.

- Fine-Tuning After a Test Print: Even a well-leveled bed may need slight tweaks based on the first layer’s appearance.

Pros of Manual Bed Leveling:

✅ Simple and inexpensive—no extra hardware required.

✅ Provides direct control for fine adjustments.

✅ Works on most standard 3D printers without modifications.

Cons of Manual Bed Leveling:

❌ Can be time-consuming and frustrating for beginners.

❌ Requires periodic re-leveling as the bed shifts over time.

❌ Prone to slight human error in judgment.

Automatic Bed Leveling: How It Works

Automatic bed leveling relies on sensors, such as a BLTouch or an inductive probe, to measure the height at multiple points across the bed. The printer then compensates for uneven surfaces by adjusting the nozzle position dynamically during prints.

Pros of Automatic Bed Leveling:

✅ Eliminates manual guesswork, making it beginner-friendly.

✅ Reduces leveling frequency—once calibrated, it requires minimal adjustments.

✅ More consistent results, especially on larger print beds.

Cons of Automatic Bed Leveling:

❌ Requires additional hardware and installation.

❌ More expensive than manual leveling methods.

❌ Can be tricky to set up and troubleshoot if calibration goes wrong.

Both methods are widely used, but for beginners, manual leveling is a valuable skill to learn before transitioning to auto-leveling. In the next section, we’ll dive into a step-by-step guide for manual bed leveling!

3. Step-by-Step Manual Bed Leveling Guide

Preparing the Printer for Leveling

Before adjusting the bed, follow these key preparation steps:

- Ensure the bed is clean: Remove any leftover filament or debris.

- Preheat the bed: If using a heated bed, bring it to printing temperature to account for material expansion.

- Home the printer: Move the nozzle to its default zero position to begin leveling accurately.

Using the Paper Test Method

The paper test is a simple way to gauge the nozzle’s distance from the bed:

- Place a standard sheet of paper on the print bed.

- Move the nozzle to the first corner, lowering it until it lightly grips the paper.

- Adjust the bed screw in small increments until the paper has slight resistance but can still slide.

- Repeat this process for all corners and the center of the bed.

Adjusting Bed Screws for Optimal Results

Once the paper test is complete, fine-tuning is necessary:

- Check for uniformity: The paper should feel equally resistant at all test points.

- Make small adjustments: Over-tightening can cause first-layer issues, so adjust carefully.

- Perform a test print: Run a simple first-layer print to confirm consistency across the bed.

Checking and Fine-Tuning the Level After Test Prints

Even after successful leveling, occasional tweaks may be needed:

- Look for signs of uneven extrusion: If one side appears too squished or too loose, adjust accordingly.

- Monitor print adhesion: If corners lift or warp, ensure the bed is correctly leveled and possibly adjust temperature settings.

- Recheck after a few prints: Natural wear and vibrations may cause slight misalignment over time.

With manual bed leveling mastered, beginners will have a reliable foundation for successful prints. Next, we’ll explore automatic bed leveling and how it works!

4. Automatic Bed Leveling: How It Works

How Sensor-Based Leveling Compensates for Uneven Beds

Automatic bed leveling systems use sensors to measure the bed’s height at multiple points, creating a mesh or compensation map. During printing, the nozzle dynamically adjusts to maintain an even first layer, reducing the need for frequent manual tuning.

Setting Up and Calibrating an Auto-Leveling System

If your printer supports automatic bed leveling, here’s how to set it up:

- Install the sensor: Common choices include BLTouch, inductive probes, or capacitive sensors.

- Update the firmware: Ensure your printer’s firmware is compatible and configured for bed leveling.

- Run the calibration routine: Most printers allow you to measure multiple points across the bed to create an accurate level map.

- Save and test: Once calibrated, perform a test print to verify proper compensation and first-layer adhesion.

Troubleshooting Common Auto-Leveling Issues

- Sensor misalignment: If the probe isn’t positioned correctly, the bed mapping may be inaccurate.

- Z-offset issues: The nozzle may start too high or too low—adjust the Z-offset value for proper first-layer squish.

- Firmware settings: Incorrect configurations can lead to poor results—double-check your firmware parameters and re-run calibration if necessary.

https://3dprintingtips.com/3d-printer/Automatic bed leveling significantly reduces the hassle of manual adjustments, making 3D printing more user-friendly, especially for beginners.

5. Common Bed Leveling Mistakes & How to Fix Them

1. Over-Tightening or Uneven Screw Adjustments

One of the most common mistakes is adjusting the bed screws too aggressively. Over-tightening can lead to a warped print bed, making it difficult to achieve consistent leveling. ✅ Fix: Make small, gradual adjustments and test the bed at multiple points rather than relying on a single measurement.

2. Inconsistent Results Across Different Print Surfaces

Different bed surfaces, such as glass, PEI sheets, or textured surfaces, can affect how the filament adheres. Beginners may find that what works for one print surface doesn’t always work for another.

✅ Fix: Consider adjusting print temperatures and first-layer settings based on the bed material. Some surfaces require additional adhesion aids like glue sticks or hairspray.

3. Nozzle Too Close or Too Far from the Bed

If the nozzle is too close, filament won’t extrude properly, leading to an overly squished first layer. If it’s too far, adhesion suffers, causing warping or print failure.

✅ Fix: Use the Z-offset setting (if available) to fine-tune the nozzle distance after initial leveling. Perform a test print to verify correct first-layer adhesion.

4. Relying Too Much on Auto-Leveling Without Calibration

Auto-leveling helps compensate for uneven beds, but it doesn’t fix poor calibration. If the initial setup is incorrect, auto-leveling may struggle to compensate properly.

✅ Fix: Regularly check sensor positioning and recalibrate as needed. Run a full bed-mesh leveling process to ensure accuracy.

5. Ignoring Maintenance & Regular Re-Leveling

Over time, vibrations, temperature changes, and wear can cause the bed to shift slightly, affecting print quality. Even printers with auto-leveling benefit from occasional maintenance.

✅ Fix: Periodically check bed screws, print adhesion, and re-run leveling procedures every few weeks to maintain consistency.

With these common mistakes addressed, beginners can achieve better results and minimize print failures.

6. Final Tips & Best Practices for Beginners

1. Regular Maintenance for a Consistently Level Bed

Even after successful leveling, small shifts can occur due to wear, vibrations, or temperature changes.

✅ Best Practice: Make a habit of checking bed leveling every few prints to avoid unexpected issues.

2. Choosing the Right Bed Surface for Different Filaments

Different materials adhere better to specific bed surfaces.

✅ Best Practice: Use glass or PEI sheets for PLA filament, while textured or heated beds work well for ABS and PETG. Adjust adhesion aids accordingly.

3. Understanding When to Re-Level the Bed

Signs that it’s time to re-level include:

- Uneven first layers (some areas too squished or too loose).

- Adhesion problems, like warping or peeling prints.

- Bed screws shifting due to vibrations over time.

✅ Best Practice: Run a quick leveling check whenever you switch filaments, modify settings, or notice inconsistent results.

4. Using Test Prints to Confirm Leveling Accuracy

Before jumping into a complex print, running a simple first-layer test can help catch small leveling issues.

✅ Best Practice: Consider printing a thin rectangular layer across the bed to check uniform adhesion.

5. Combining Auto-Leveling with Manual Adjustments

Even auto-leveling benefits from occasional manual tweaks for best results.

✅ Best Practice: Use Z-offset tuning in combination with auto-leveling to fine-tune your first layer.

With these tips in mind, beginners can ensure consistently smooth prints with minimal frustration!