Introduction

Nylon filament has earned a reputation as one of the most durable, versatile, and high-performing materials in 3D printing. Its exceptional strength, flexibility, and resistance to wear and chemicals make it indispensable for demanding applications such as custom gears, functional prototypes, and load-bearing components. Whether you’re an experienced professional or a hobbyist looking to expand your capabilities, Nylon filament offers unparalleled opportunities to push the limits of 3D printing, and should be in your filaments arsenal.

Anecdote:

One of my most impressive projects with Nylon filament was printing a custom gear for a DIY robotics kit. The gear not only handled intense stress but remained fully functional over repeated usage—a perfect example of Nylon’s unmatched strength and durability.

1. What is Nylon Filament?

Definition and Composition

Nylon is a synthetic polymer known for its exceptional strength, flexibility, and durability. In the context of 3D printing, Nylon filament is widely used in engineering, automotive, and industrial applications due to its ability to withstand high stress and wear.

Key Components of Nylon:

- Polyamide Structure: Provides strength, elasticity, and excellent abrasion resistance.

- Additives: Depending on the variant, Nylon may include fillers like carbon fiber for added strength or flexibility.

Key Properties

Nylon filament’s unique characteristics make it one of the most versatile materials available for 3D printing:

- High Strength and Durability: Nylon excels in high-strength 3D prints and applications requiring load-bearing parts.

- Flexibility: Its slight elasticity allows it to absorb impacts, ideal for flexible and durable parts.

- Abrasion Resistance: Perfect for abrasion-resistant designs like gears and mechanical components.

- Chemical Resistance: Nylon withstands exposure to oils, greases, and many solvents, expanding its use in chemical-resistant applications.

- Thermal Stability: It retains its mechanical properties under moderate heat, making it suitable for automotive and aerospace projects.

Anecdote:

I once used Nylon to create bushings for a model car prototype. Its flexibility and wear resistance ensured a smooth and durable fit, showcasing why Nylon is often chosen for functional prototypes.

Why Choose Nylon Filament?

Nylon filament is an advanced material that meets the demands of engineers, designers, and hobbyists who require strength, durability, and flexibility in their projects. Its versatility makes it suitable for a wide range of applications, from medical and prosthetic designs to custom gears and mechanical parts.

Specialty Uses:

- Industrial Applications: Nylon’s mechanical strength makes it indispensable for load-bearing components in machinery and robotics.

- Wear-Resistant Designs: From gears to bushings, Nylon’s abrasion resistance ensures longevity.

2. Benefits and Applications of Nylon Filament

Nylon filament is a powerhouse material in 3D printing, prized for its combination of strength, flexibility, and chemical resistance. Whether you’re designing load-bearing components, functional prototypes, or wear-resistant designs, Nylon’s unique properties make it indispensable for complex and high-performance projects.

Advantages of Nylon Filament

- High Strength and Durability Nylon’s superior tensile strength ensures it can withstand significant loads and repeated stress, making it ideal for Nylon filament for industrial applications. Anecdote: I once printed a custom tool handle with Nylon filament. The result was exceptionally strong, handling substantial force without cracking or bending—an ideal material for heavy-duty usage.

- Flexibility Unlike more rigid filaments like PLA or ABS, Nylon retains flexibility, allowing it to absorb impacts and stresses without breaking. This property makes it perfect for flexible and durable parts like hinges or clips. Anecdote: While prototyping a wearable joint brace, Nylon’s slight elasticity provided both comfort and durability, outperforming other materials.

- Abrasion Resistance Nylon is highly resistant to wear and tear, making it the go-to material for abrasion-resistant designs like gears, pulleys, and bushings.

- Chemical Resistance Nylon can withstand exposure to oils, greases, and most solvents, broadening its applications for chemical-resistant projects in industrial and automotive settings.

- Thermal Stability Its ability to perform under moderate heat makes Nylon ideal for Nylon filament for automotive and aerospace projects where thermal resistance is essential.

- Lightweight Despite its strength, Nylon is lightweight, which is advantageous for applications requiring reduced weight without sacrificing durability.

Common Applications of Nylon Filament

1. Gears and Mechanical Parts

Nylon’s high strength and abrasion resistance make it the material of choice for custom gears and mechanical parts that endure repetitive motion and high stress.

2. Functional Prototypes

Thanks to its flexibility and durability, Nylon excels in prototyping high-strength 3D prints for testing in real-world conditions.

3. Automotive and Aerospace Components

Nylon’s thermal stability and chemical resistance suit demanding environments, making it invaluable for automotive and aerospace projects like lightweight brackets, ducts, or housings.

4. Medical and Prosthetic Applications

Nylon’s biocompatibility and strength allow for innovative designs in medical and prosthetic applications, such as joint braces, splints, or custom orthopedic supports.

5. Outdoor and Weatherproof Designs

With its resistance to UV exposure and moisture, Nylon performs well in weatherproof designs like custom garden tools, outdoor fixtures, or sporting goods.

Specialty Applications

Nylon filament’s unique properties allow it to shine in specific scenarios:

- Dual-Extrusion Projects: Combine Nylon with rigid materials for hybrid designs that require both flexibility and structural strength.

- Abrasion-Intensive Components: Use Nylon for wear-resistant parts that need to endure consistent friction, such as bushings or sliders.

Why Nylon Stands Out

Nylon filament’s unparalleled combination of flexibility, strength, and wear resistance makes it the preferred material for advanced engineering and demanding applications. Its ability to perform under stress, exposure to chemicals, and moderate heat ensures consistent reliability.

Anecdote:

During a robotics project, I designed gearboxes using Nylon filament. The material’s abrasion resistance and smooth surface made it the perfect choice for gears that operated seamlessly under prolonged use and stress.

3. Printing with Nylon Filament

Printing with Nylon filament can be challenging due to its hygroscopic nature and flexibility. However, with the right equipment, settings, and precautions, Nylon can yield high-quality, durable prints for complex applications like custom gears and mechanical parts or chemical-resistant projects.

Printer Compatibility

Nylon filament requires specific printer capabilities to ensure consistent performance:

- Heated Bed: A heated bed is essential to prevent warping. Ideal bed temperatures range from 60°C to 90°C.

- Enclosed Printer: Nylon performs best in a controlled environment to prevent rapid cooling or exposure to moisture during printing.

- Nozzle Requirements: Hardened steel nozzles are recommended for abrasive Nylon variants like carbon fiber-filled filaments.

Anecdote:

In my experience, switching to an enclosed printer while working on weatherproof designs dramatically reduced warping issues, delivering smooth and reliable results.

Optimal Settings for Nylon Filament

Using the right printer settings ensures consistent, high-quality results. Below is a table of general recommendations for Nylon:

| Setting | Recommended Value |

|---|---|

| Nozzle Temperature | 240°C–270°C |

| Bed Temperature | 60°C–90°C |

| Print Speed | 40–60 mm/s |

| Cooling Fan Usage | Off |

Key Considerations:

- Nozzle Temperature: Higher temperatures improve layer bonding but may increase stringing. Fine-tune based on filament brand.

- Bed Adhesion: Use adhesion aids like glue stick, painter’s tape, or PEI sheets for better grip.

- Cooling Fan: Avoid cooling fans as they can interfere with layer adhesion and cause warping.

Troubleshooting Tips for Nylon Filament

Despite its advantages, Nylon can pose unique challenges. Here’s how to address common issues:

1. Moisture Absorption

- Cause: Nylon absorbs water quickly, leading to bubbling during extrusion.

- Solution: Store Nylon in airtight containers with desiccant packs and dry it before printing if necessary.

2. Warping

- Cause: Rapid cooling can cause Nylon prints to shrink unevenly and warp.

- Solution: Use an enclosed printer and increase bed temperature to ensure gradual cooling.

3. Stringing

- Cause: Nylon’s high flow rate can result in filament oozing between parts.

- Solution: Enable retraction and adjust nozzle temperature to reduce excessive flow.

Anecdote:

While printing durable spacers for automotive and aerospace projects, I encountered warping issues that threatened to compromise the design. Utilizing a heated enclosure and adhesive sheets resolved the problem, producing flawless, stress-resistant parts.

Specialty Settings for Nylon Variants

Certain Nylon variants require adjustments for optimal results:

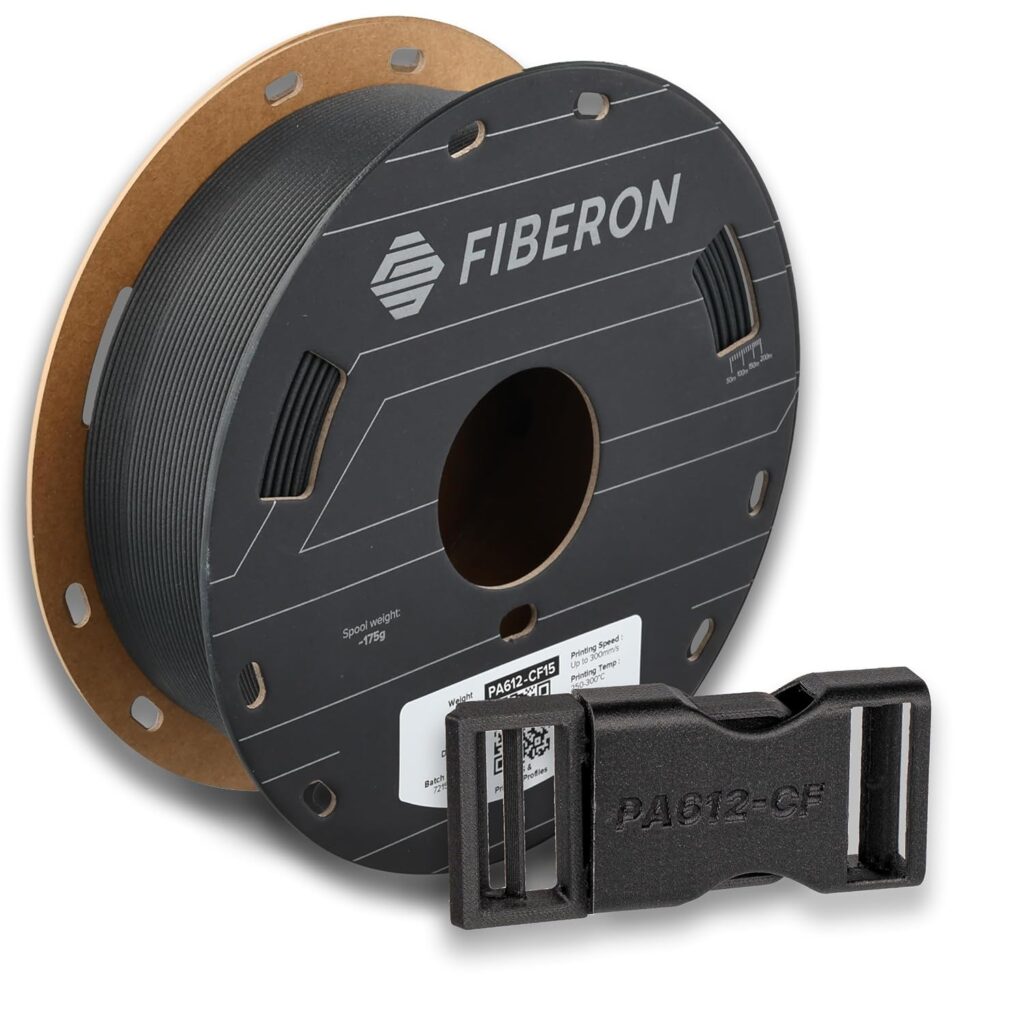

- Carbon Fiber Nylon: Increase nozzle temperature slightly for enhanced bonding and durability.

- Flexible Nylon: Lower print speed to improve precision and prevent buckling during extrusion.

Printing with Nylon filament can unlock its full potential for strong, flexible, and wear-resistant designs.

4. Handling and Storage of Nylon Filament

Proper handling and storage are critical for Nylon filament due to its hygroscopic nature, which means it absorbs moisture from the air. Failure to store Nylon correctly can result in bubbling, poor adhesion, and inconsistent prints. By following the right precautions, you can ensure its longevity and optimize its performance for high-strength 3D prints and wear-resistant designs.

Storage Tips for Nylon Filament

- Airtight Containers: Always store Nylon filament in sealed containers or resealable bags with desiccant packs to keep it dry. Exposure to humidity can degrade its properties and affect print quality.

- Filament Dry Box: In regions with high humidity, consider using a filament dry box to maintain ideal storage conditions. This is particularly useful for Nylon filament for load-bearing components and other critical applications.

- Avoid Sunlight and Heat: Prolonged exposure to UV light and heat can weaken Nylon’s mechanical properties. Keep your filament in a cool, dark location.

Anecdote:

I once left a spool of Nylon out overnight in a humid workspace, and the next day, my prints bubbled and warped. After investing in a filament dry box and resealing unused spools, I’ve had no further issues with moisture affecting Nylon’s performance.

How to Dry Nylon Filament

If Nylon filament absorbs moisture, drying it can often restore its quality. Here are effective drying methods:

- Filament Dryer: Use a filament dryer at 70°C–80°C for several hours to eliminate excess moisture.

- Oven Drying: Place the filament in an oven at a low temperature (no higher than 80°C) and monitor closely to avoid melting.

- Vacuum-Sealed Desiccants: For minor moisture absorption, reseal Nylon with fresh desiccants for 24–48 hours to reduce humidity exposure.

Handling Nylon Filament During Printing

Proper handling during the printing process prevents jams, tangles, and other operational challenges:

- Inspect for Moisture Damage: Before loading Nylon filament, check for signs of bubbling, uneven extrusion, or hazy surface texture.

- Prevent Tangling: Nylon’s flexibility can cause spooling issues, so unspool it carefully to ensure consistent feeding.

Specialty Considerations:

For specialty variants like carbon fiber Nylon filament, maintain low humidity during storage to preserve its strength and unique properties.

Long-Term Storage Techniques

If you plan to store Nylon filament for extended periods:

- Rotate Usage: Use older spools first to avoid prolonged exposure to air.

- Label Each Spool: Include the purchase date for easy tracking of filament age.

- Store in Controlled Environments: Maintain stable temperature and humidity levels, especially for Nylon filament for automotive and aerospace projects where performance is critical.

Why Proper Storage Matters

Improper storage can lead to wasted material, printing frustrations, and compromised parts. By adopting these best practices, Nylon filament retains its strength, flexibility, and reliability for demanding applications like custom gears and mechanical parts.

Anecdote:

During a collaborative prototyping session, my teammate struggled with Nylon bubbling issues due to improper storage. Introducing them to airtight containers and filament drying techniques transformed their results, ensuring smooth, consistent prints for the rest of the project.

With proper handling and storage, Nylon filament remains a dependable material for both innovative and industrial-grade projects.

5. Popular Brands and Variants of Nylon Filament

Nylon filament’s versatility and durability have made it a favorite among professionals and hobbyists alike. With options ranging from affordable to industrial-grade, there’s a Nylon filament for every application, from abrasion-resistant designs to custom gears and mechanical parts.

Top Nylon Filament Brands

| Brand | Features | Price Range |

|---|---|---|

| Taulman 3D | Premium Nylon filaments with exceptional strength | $$$ |

| Polymaker | High-performance Nylon variants, including carbon fiber-filled options | $$$ |

| Hatchbox | Affordable and reliable, ideal for hobbyists | $$ |

| eSUN | Flexible and durable, with affordable pricing | $$ |

| MatterHackers | Specialized Nylon filaments for industrial-grade applications | $$$ |

Anecdote:

While creating functional prototypes for a robotics project, I used Taulman Nylon for its outstanding abrasion resistance and strength. The parts endured rigorous testing without showing signs of wear, proving why Taulman 3D is often the go-to for high-performance applications.

Specialty Nylon Variants

Nylon filament is available in specialty types tailored to specific needs and challenges:

1. Carbon Fiber Nylon

Infused with carbon fiber, this variant enhances strength and stiffness, making it perfect for abrasion-resistant designs and load-bearing parts.

2. Flexible Nylon

Low-Shore Nylon grades provide maximum elasticity for applications like medical and prosthetic designs or wearable components.

3. UV-Resistant Nylon

Designed for outdoor and weatherproof designs, UV-resistant Nylon retains durability under prolonged sunlight exposure.

4. Nylon Alloy Filaments

Alloys combine Nylon with other polymers for improved thermal resistance or chemical durability, expanding its use in automotive and aerospace projects.

Comparing Nylon Filament Brands

| Feature | Taulman 3D | Polymaker | Hatchbox | eSUN |

|---|---|---|---|---|

| Industrial-Grade | ✅ Premium | ✅ High-Grade | ⚠ Moderate | ⚠ Limited |

| Abrasion Resistance | ✅ Exceptional | ✅ Exceptional | ⚠ Moderate | ✅ Reliable |

| Flexibility | ✅ Good | ✅ Superior | ⚠ Limited | ✅ Good |

| Price | $$$ Premium | $$$ Premium | $$ Affordable | $$ Affordable |

Each brand and specialty variant offers unique advantages for different projects, whether you prioritize cost-efficiency, durability, or advanced performance for Nylon filament for industrial applications.

Why Specialty Variants Matter

Specialty Nylon filaments allow users to tailor their designs to specific challenges. From carbon fiber-filled Nylon filament for high-strength components to flexible Nylon for ergonomic designs, the right variant can elevate any project.

Anecdote:

During a competition, I used UV-resistant Nylon to print lightweight brackets for an outdoor drone. The material’s durability and resistance to sunlight ensured flawless performance throughout the event, highlighting the importance of selecting the correct variant for environmental conditions.

Nylon filament offers unmatched strength and versatility, with trusted brands and specialty variants catering to a wide range of applications.

6. Comparing Nylon Filament to Other Filaments

Nylon filament stands out for its combination of strength, flexibility, and chemical resistance, but how does it compare to other widely used filaments like PETG, ABS, and TPU? Understanding these differences helps users choose the right material for projects ranging from load-bearing components to medical applications.

\Nylon vs PETG Filament

PETG filament offers durability and weather resistance, but Nylon provides greater strength and flexibility for industrial-grade applications.

| Criteria | Nylon Filament | PETG Filament |

|---|---|---|

| Strength | ✅ Exceptional | ⚠ Moderate |

| Flexibility | ✅ Moderate | ⚠ Low |

| Chemical Resistance | ✅ High | ⚠ Limited |

| Ease of Printing | ⚠ Moderate | ✅ Easier |

| Weather Resistance | ✅ Good | ✅ Excellent |

Key Takeaways:

- Nylon is better suited for abrasion-resistant designs and parts requiring superior tensile strength.

- PETG excels in weatherproof designs and projects needing UV durability.

Anecdote:

While creating custom bushings for machinery, Nylon’s strength and abrasion resistance proved far superior to PETG for parts exposed to continuous motion and stress.

Nylon vs ABS Filament

ABS filament is known for its heat resistance and rigid properties, while Nylon provides flexibility and better wear resistance for complex applications.

| Criteria | Nylon Filament | ABS Filament |

|---|---|---|

| Strength | ✅ Strong | ✅ Strong |

| Flexibility | ✅ Moderate | ❌ Low |

| Heat Resistance | ✅ Moderate | ✅ High |

| Abrasion Resistance | ✅ High | ⚠ Moderate |

| Fume Emissions | ✅ Low | ❌ High |

Key Takeaways:

- Nylon is ideal for abrasion-resistant designs and parts requiring flexibility, while ABS shines in high-heat environments.

- ABS requires a more controlled printing setup, whereas Nylon’s moisture sensitivity demands proper storage.

Anecdote:

For a project involving lightweight drone brackets, Nylon’s flexibility and chemical resistance outperformed ABS, which became brittle under repeated stress.

Nylon vs TPU Filament

TPU filament is prized for its elasticity and shock absorption, but Nylon’s superior strength and abrasion resistance make it better suited for load-bearing and wear-intensive applications.

| Criteria | Nylon Filament | TPU Filament |

|---|---|---|

| Strength | ✅ Strong | ⚠ Moderate |

| Flexibility | ⚠ Moderate | ✅ High |

| Abrasion Resistance | ✅ High | ✅ Good |

| Chemical Resistance | ✅ High | ⚠ Limited |

| Ease of Printing | ⚠ Challenging | ✅ Easier |

Key Takeaways:

- Nylon excels in high-strength 3D prints and abrasion resistance for gears and mechanical parts.

- TPU is better for flexible and durable parts like phone cases and wearable devices.

Anecdote:

While prototyping gears for a robotics kit, Nylon’s strength and abrasion resistance ensured seamless operation under heavy load, outperforming TPU’s flexibility, which was less suitable for this application.

When to Choose Nylon Filament

Nylon filament’s combination of strength, flexibility, and resistance to wear makes it indispensable for demanding applications, from abrasion-resistant designs to chemical-resistant projects. While PETG, ABS, and TPU excel in specific areas, Nylon’s versatility ensures reliable results for both functional prototypes and high-stress components.

7. Environmental and Safety Considerations for Nylon Filament

Nylon filament is a high-performance material with incredible strength and durability, but its synthetic composition raises environmental and safety concerns. By adopting responsible handling practices and considering recycling options, users can minimize Nylon’s environmental footprint while ensuring a safe and efficient printing process.

Environmental Impact of Nylon Filament

Nylon’s long-lasting nature is both a benefit and a challenge. While it’s not biodegradable, its durability reduces the need for reprints, thereby minimizing material waste.

Recycling Nylon:

- Recycling Programs: While less common than PLA or PETG recycling programs, Nylon can sometimes be recycled locally. Contact your local recycling center for compatibility.

- Recycling Solutions: Specialty services or programs may offer take-back initiatives for Nylon materials.

- Creative Repurposing: Failed Nylon prints can be reused in crafts, like creating functional spacers or simple decorative items.

Anecdote:

During a community workshop, I noticed a creative approach where failed Nylon parts were repurposed into durable, lightweight tool organizers—an inspiring example of practical upcycling.

Safe Printing Practices

Although Nylon is generally safe to print, some precautions ensure a healthier and more efficient printing environment:

- Ventilation: Nylon emits minimal fumes, but printing in a well-ventilated space reduces odor and ensures fresh airflow.

- Dry Storage: Keep Nylon filament dry before and during printing to prevent bubbling or inconsistencies.

- Temperature Monitoring: Overheating Nylon can degrade its structure and emit unpleasant odors. Stick to the recommended temperature range (240°C–270°C) for optimal performance.

Anecdote:

While printing components for medical and prosthetic applications, a teammate noticed bubbling caused by residual moisture in the Nylon filament. After drying the spool, the prints improved dramatically, highlighting the importance of proper handling.

Nylon’s Contribution to Sustainable Printing

While not inherently eco-friendly, Nylon filament’s strength and longevity reduce the need for frequent replacements, aligning with sustainable practices. Its applications in functional prototypes and abrasion-resistant designs often outlast those made from less durable materials.

Sustainability Benefits:

- Durability: Nylon’s ability to withstand wear and tear ensures that parts have longer lifespans, reducing waste.

- Reuse Potential: Creative repurposing of failed prints helps extend the material’s lifecycle.

By prioritizing safe handling and exploring creative recycling options, Nylon filament users can make informed choices that balance performance with environmental responsibility.

8. Frequently Asked Questions (FAQs)

Nylon filament’s versatility and strength make it a favorite for demanding 3D printing applications. Below are answers to commonly asked questions, designed to help users optimize their experience with this remarkable material.

1. What is the best Nylon filament for 3D printing?

The best Nylon filament depends on your needs:

- Taulman 3D: Exceptional durability for abrasion-resistant designs and industrial-grade components.

- Polymaker: Offers high-performance options like carbon fiber-filled Nylon for Nylon filament for industrial applications.

- Hatchbox or eSUN: Affordable yet reliable options for hobbyists exploring Nylon.

Anecdote:

For a project requiring custom gears and mechanical parts, I used Taulman Nylon. Its strength and abrasion resistance resulted in flawless prints that functioned seamlessly under stress.

2. How do I print successfully with Nylon filament?

Printing with Nylon requires specific adjustments:

- Use a nozzle temperature of 240°C–270°C and a bed temperature of 60°C–90°C.

- Employ adhesion aids like glue stick or PEI sheets to prevent warping.

- Ensure your printer has an enclosed build chamber for better temperature control.

These tips align with Nylon filament troubleshooting tips for beginners to ensure high-quality prints.

3. How do I store Nylon filament to prevent moisture damage?

Nylon’s hygroscopic nature makes airtight storage essential. Use sealed containers with desiccant packs to keep the filament dry. For extra protection in humid environments, consider a filament dry box.

4. What are Nylon filament temperature settings for optimal prints?

Nylon prints best with the following settings:

- Nozzle Temperature: 240°C–270°C

- Bed Temperature: 60°C–90°C

- Cooling Fan: Turned off to improve layer bonding.

5. Can Nylon filament be recycled?

While not as commonly recycled as PLA, Nylon filament can be repurposed:

- Recycling Programs: Check with local centers for Nylon recycling options.

- DIY Recycling: Failed prints can be shredded and reused in new projects.

- Upcycling: Failed parts can be repurposed for functional uses like spacers or tool organizers.

6. What are common troubleshooting tips for Nylon filament printing issues?

Here are solutions to common challenges:

- Warping: Use an enclosed printer and adhesive sheets to reduce shrinkage.

- Moisture Absorption: Dry the filament at 70°C–80°C before printing to eliminate bubbling.

- Stringing: Enable retraction and adjust nozzle temperature to minimize oozing.

7. How does Nylon filament compare to PETG or ABS?

- Nylon is stronger and more abrasion-resistant than PETG but less weatherproof.

- Nylon offers better flexibility and durability than ABS but lacks its high-heat tolerance.

8. Are there specialty Nylon filaments available?

Yes, Nylon comes in several specialty variants:

- Carbon Fiber Nylon: Ideal for abrasion-resistant designs and high-strength applications.

- Flexible Nylon: Perfect for medical and prosthetic applications.

- UV-Resistant Nylon: Best for outdoor and weatherproof designs.

9. What are the best applications for Nylon filament?

Nylon excels in:

- Custom gears and mechanical parts

- Functional prototypes

- Abrasion-resistant tools like bushings

- Medical and wearable devices

- Automotive and aerospace components

10. How do I safely print with Nylon filament?

To ensure safe printing:

- Work in a ventilated area to reduce minor fumes.

- Monitor temperature settings to avoid overheating.

- Keep Nylon dry before and during printing for consistent results.

These FAQs provide actionable solutions and insights to help users make the most of Nylon filament for both creative and industrial applications.

9. Best Nylon Filament Brands

- MatterHackers PRO Series Nylon – Premium nylon with tight tolerances and strong impact resistance.

- MatterHackers NylonG – Glass-fiber-reinforced nylon for added strength and durability.

- MatterHackers NylonX – Carbon fiber-infused nylon for high wear resistance and stiffness.

- Overture Nylon – Affordable nylon filament with good printability.

- Hatchbox PA Nylon – Premium nylon with high stiffness.

- Taulman3D Nylon 230 – Low-temperature nylon for easier printing.

- eSun Natural Nylon – Reliable nylon filament with strong layer adhesion.

- Polymaker PA6-GF Nylon – Glass-fiber-reinforced nylon for industrial applications.

- Ultimaker Nylon – Optimized for Ultimaker printers, high consistency.

These brands are widely recommended for their printability, durability, and overall performance.

10. Nylon Brands Some Users Recommend Avoiding

- Ice 9 Ridge Nylon – Reports of poor layer adhesion, brittleness, and inconsistent additives.

- Geeetech Nylon – Some users report extreme diameter inconsistencies, ranging from 1.7mm to 3mm.

- Reprapworld Generic Nylon – Reports of frequent breakage, poor spooling, and extrusion issues.

- No-name budget nylon brands – Often suffer from moisture absorption and inconsistent quality.

Nylon can be tricky to print, requiring dry storage and precise settings, so filament quality plays a big role in successful prints. If you’re unsure, checking recent reviews and community feedback can help identify potential issues before purchasing.

11. Conclusion

Nylon filament has established itself as one of the most reliable and versatile materials in 3D printing, thanks to its unparalleled strength, flexibility, and resistance to wear and chemicals. Whether you’re designing abrasion-resistant tools, functional prototypes, or high-strength components for industrial applications, Nylon’s durability and adaptability make it an indispensable choice for creators and engineers.

Key Takeaways

- Durability and Strength: Nylon is the go-to material for abrasion-resistant designs and parts that endure continuous stress and motion.

- Flexibility and Versatility: Its slight elasticity makes it ideal for medical and prosthetic applications and custom gears in machinery.

- Specialized Variants: Options like carbon fiber Nylon and UV-resistant Nylon broaden its uses across industries, from automotive to outdoor designs.

- Sustainability: While not biodegradable, Nylon’s long lifespan reduces waste and promotes sustainable practices in Nylon filament for industrial applications.

Anecdote:

One of the most rewarding projects I worked on was designing a set of abrasion-resistant bushings for a prototype vehicle. The Nylon filament parts not only exceeded expectations during stress testing but also highlighted how one material can elevate the success of an entire project.

Call-to-Action

Are you ready to push the boundaries of your 3D printing projects? Experiment with Nylon filament to unlock its full potential for high-strength and durable creations. Explore specialty variants like carbon fiber Nylon for tougher challenges, or test flexible Nylon for ergonomic designs. With its unique properties, Nylon empowers creators to achieve results that blend functionality and innovation.